CDW RECYCLING MOBILE PLANT 200-250T/H

NOTE: This is NOT a Process Flow Diagram

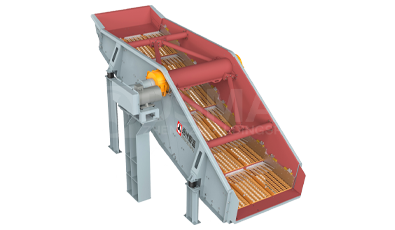

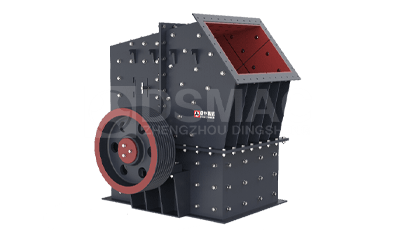

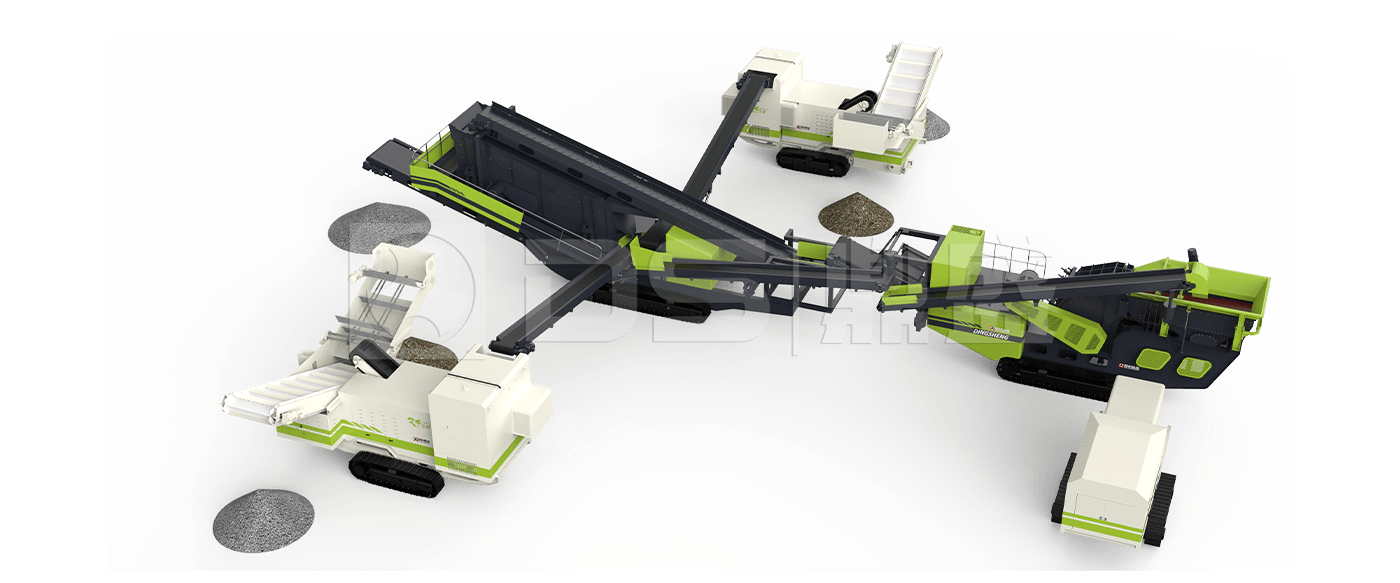

The mobile C&D waste recycling plant is also known as mobile processing module, composed of crushing unit, screening unit with feeding and conveying system, and other auxiliary devices. The difference from the static C&D waste plant is that the core equipment of mobile plant are installed on crawler or wheel type chassis. The mobile C&D waste recycling plant has been widely used in various fields such as stone/ore crushing and construction waste recycling in China.

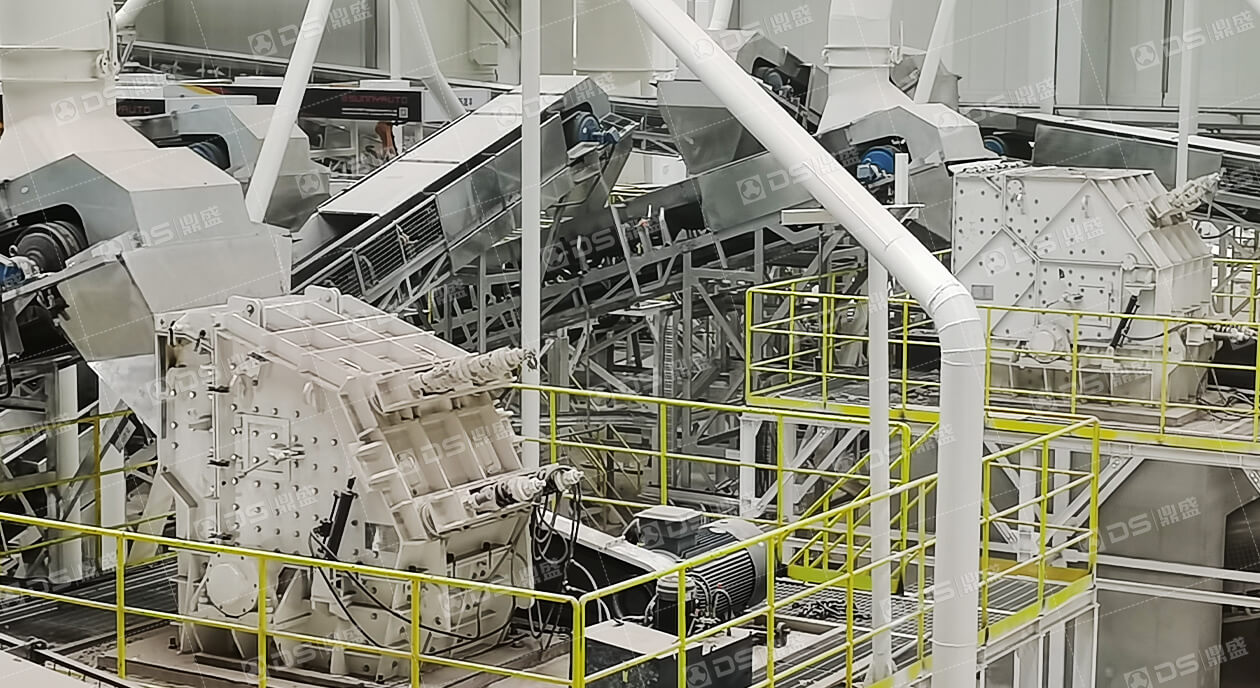

CASE OF MOBILE PLANT

POLAND 200-250T/H

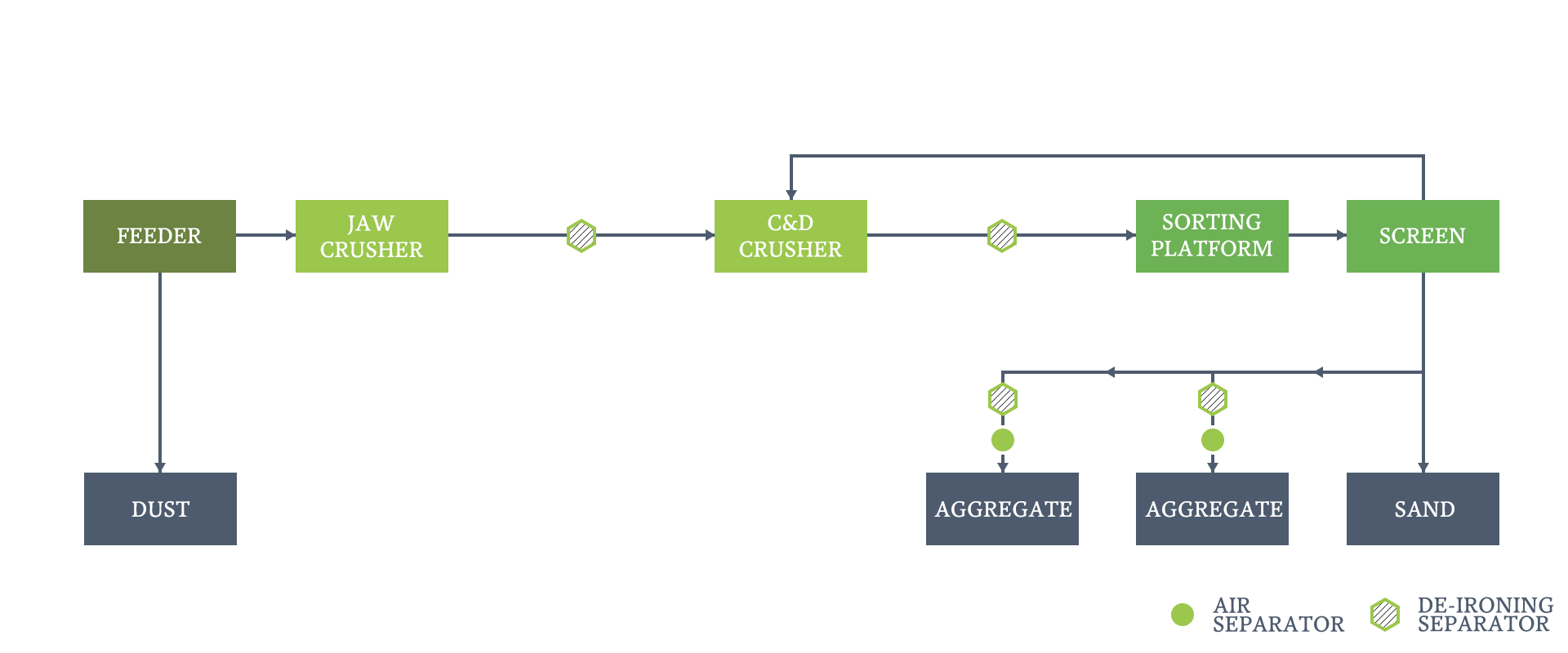

CDW RECYCLING STATIONARY PLANT 80-100T/H

NOTE: This is NOT a Process Flow Diagram

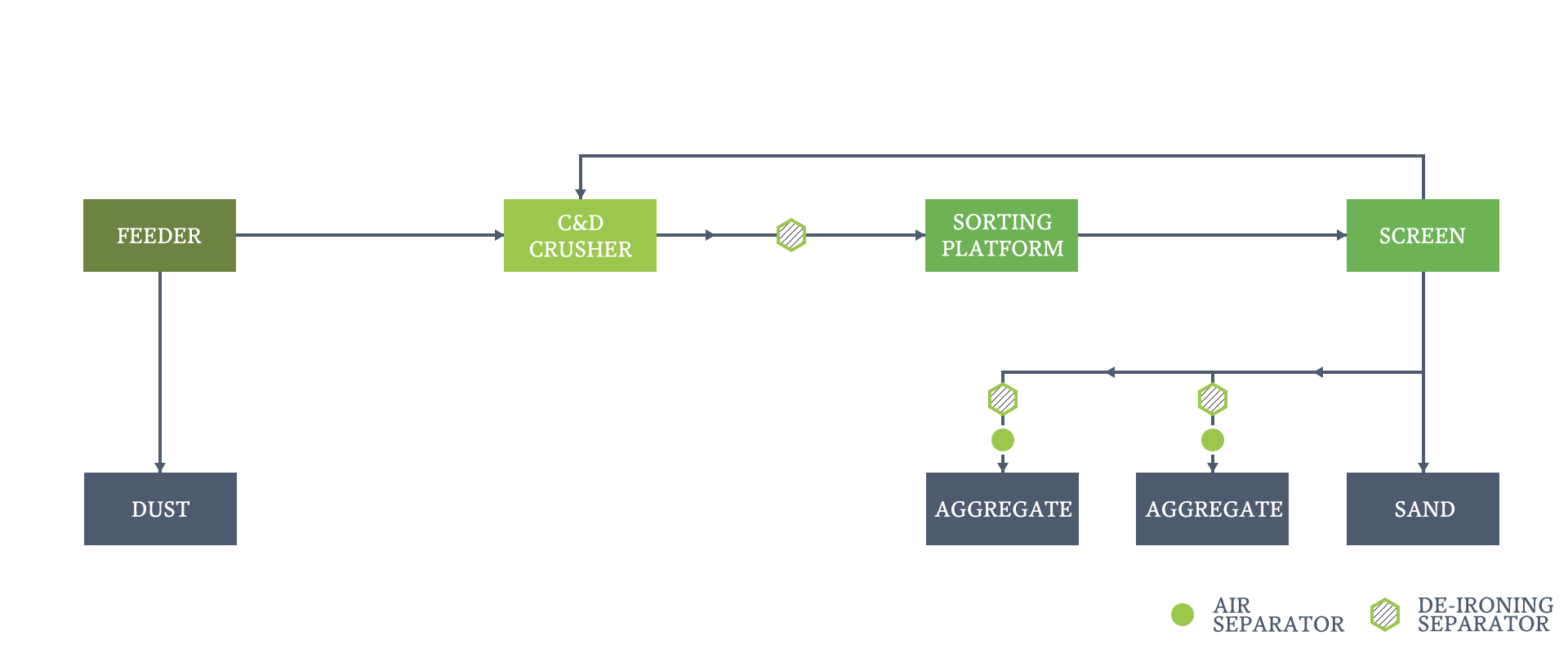

First, the collected construction and demolition waste like concrete, bricks and tiles etc. would be sent into the vibrating feeder, which can remove the dust directly, then the coarse materials are sent to the construction waste crusher for crushing. The iron material can be removed by a de-ironing separator and collected. Next, the impurities within crushed product would be sorted out. Finally, the inorganic mixed aggregates would be divided into different particle size for different purposes after second impurities removing. For example, in a fixed C&D waste recycling plant in China, the building waste is often processed into 0~5mm, 6~10mm, 10-20mm, 20-30mm gradation aggregates for multiple applications.

The finial product can be adjusted to your specific need.

The finial product can be adjusted to your specific need.

CASE OF STATIONARY PLANT

CHINA 80-100T/H

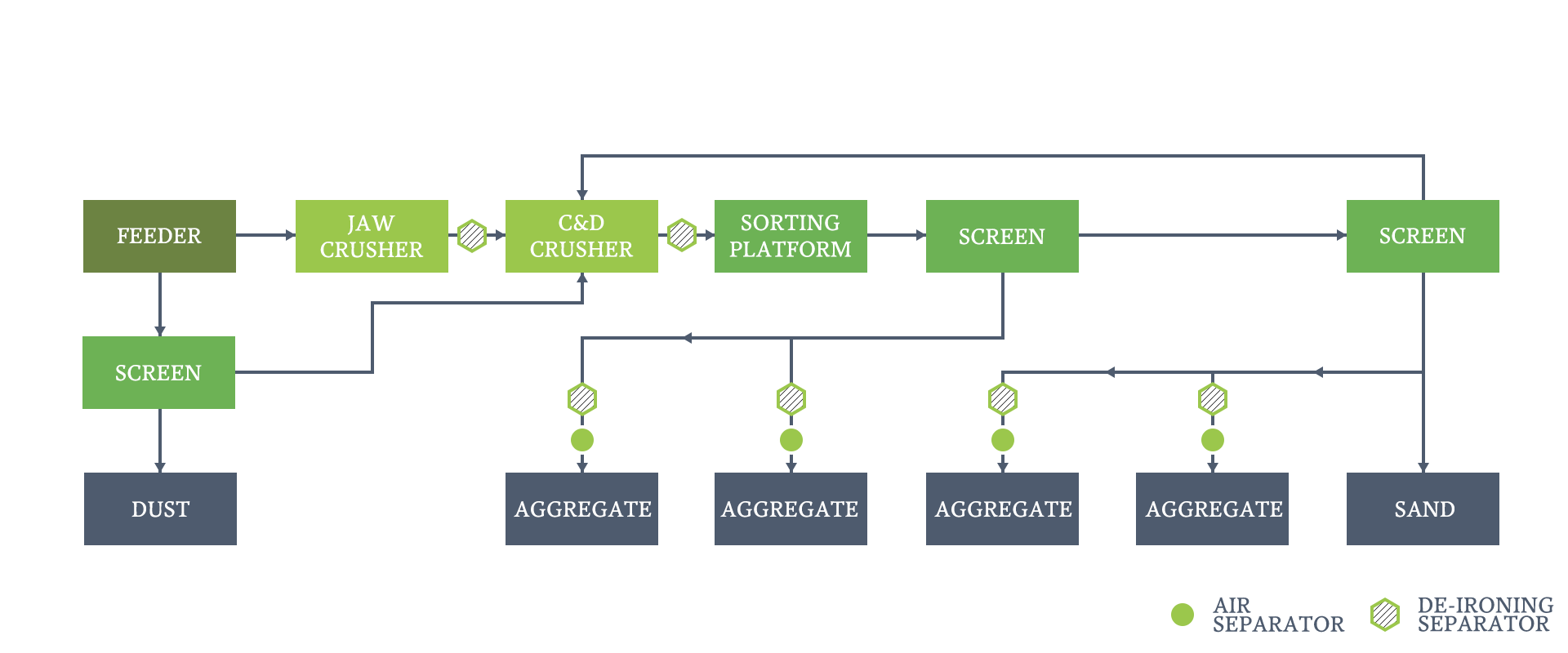

CDW RECYCLING STATIONARY PLANT 150-200T/H

NOTE: This is NOT a Process Flow Diagram

First, the collected construction and demolition waste like concrete, bricks and tiles etc. would be sent into the vibrating feeder, which can remove the dust directly, then the coarse materials are sent to primary crushing and de-ironing. Next, the material is sent to secondary crushing, being sorted and screened in the closed circuit of the process. The crushed inorganic mixed aggregates can also be divided into different particle size for different purposes after third impurities removing. For example, in a static C&D waste processing complete plant in China, the C&D waste is processed into 0~5mm, 6~10mm, 10-20mm, 20-30mm gradation aggregates for multiple applications.

The finial product can be adjusted to your specific need.

The finial product can be adjusted to your specific need.

CASE OF STATIONARY PLANT

ZAMBIA 150-200T/H

CDW RECYCLING STATIONARY PLANT 250-300T/H

NOTE: This is NOT a Process Flow Diagram

First, the collected construction and demolition waste like concrete, bricks and tiles etc. would be sent into the vibrating feeder and screen, which can remove the dust directly, then the coarse materials are sent to primary crushing and de-ironing. Next, the material and the underflow from first screen is sent to secondary crushing and de-ironing, sorted and screened twice in the closed circuit of the process. The crushed inorganic mixed aggregates can also be divided into different particle size for different purposes after third impurities removing. For example, in a static C&D waste processing complete plant in China, the C&D waste is processed into 0~5mm, 6~10mm, 10-20mm, 20-30mm gradation aggregates for multiple applications.

The finial product can be adjusted to your specific need.

The finial product can be adjusted to your specific need.

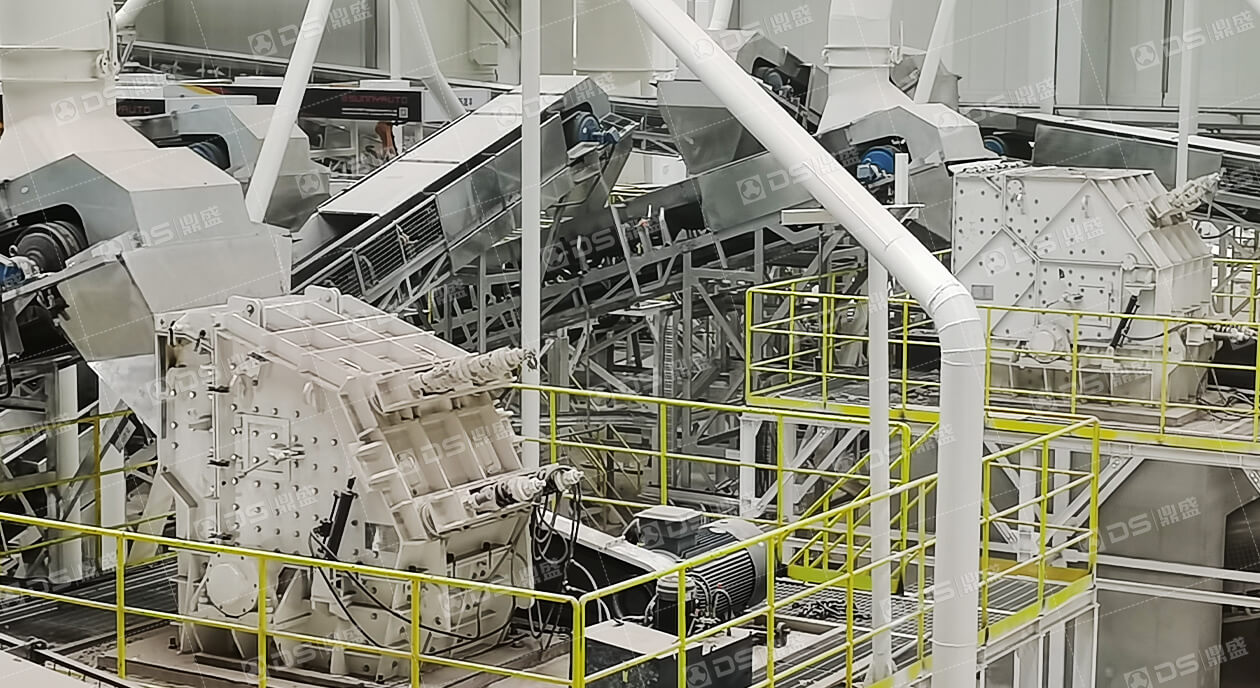

CASE OF STATIONARY PLANT

SHANGHAI 250-300T/H

INTERESTED IN OUR SOLUTIONS? YOU CAN CHECK OUT MORE ABOUT THOSE PRODUCTS

ON THEIR INDIVIDUAL PAGES OR CONTACT US FOR MORE.